O f f e rr e q u e s t

Manufactured in Serbia

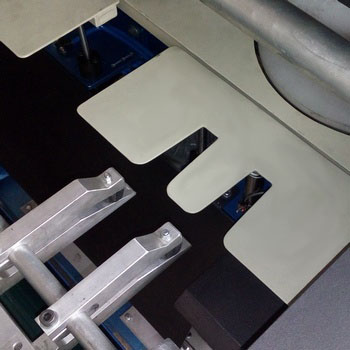

As the first Serbian manufacturer, we proudly present a fully-automatic bag making machine with hydraulic presses.

More than expected

A machine with the best price-quality ratio. Top quality, affordable price.